Engraving Services

Engraving Services

Engraving is a versatile and precise machining process used to inscribe, carve, or etch text, designs, logos, or patterns onto the surface of a workpiece. It is commonly used for personalization, identification, and decorative purposes. Engraving can be done on a wide range of materials, including metals, plastics, ceramics, glass, and wood. This catalogue provides detailed information

on the various engraving services, the processes involved, and the applications across different industries.

Our engraving services are designed to meet the highest standards of precision and quality, offering both aesthetic and functional benefits for our clients’ products and components.

Materials Processed:

- Metals: Aluminum, Brass, Stainless steel, Copper, Titanium, Tool steels, Gold, Silver.

- Plastics: Acrylic, Polycarbonate, PVC, Nylon, PEEK

- Wood and Wood Composites

- Glass and Ceramics

- Composites and Carbon Fiber

- Personalization of products (logos, names, and serial numbers).

- Markings for traceability and part identification.

- Decorative patterns for aesthetics and surface finishes.

- Industrial and functional markings for tools, dies, and molds.

- Engraved parts for electronics, medical devices, and automotive components.

Mechanical Engraving (Rotary Engraving)

Process Description:Mechanical engraving uses a rotating tool or cutter (engraving bit) to carve text, logos, or designs into the surface of the workpiece. The machine guides the tool along predefined paths, and material is progressively removed to form the engraving. It is ideal for producing detailed and consistent engravings on a variety of materials.

Machines Used:

- CNC Engraving Machines: Computer numerical control (CNC) machines are used for automated, high-precision engraving with the ability to handle intricate designs and large production volumes.

- Manual Engraving Machines: Used for one-off or custom designs that require the touch of a skilled operator.

Applications:

Serial numbers, part identification, and logos on metal or plastic components.

Engraving of decorative patterns and text on plaques, jewelry, and tools.

Engraving for machinery and equipment parts to improve traceability and ease of maintenance

Key Features:

High accuracy for fine details and deep engraving.

Suitable for a wide range of materials.

Ideal for large or small volumes of production, with fast turnaround times

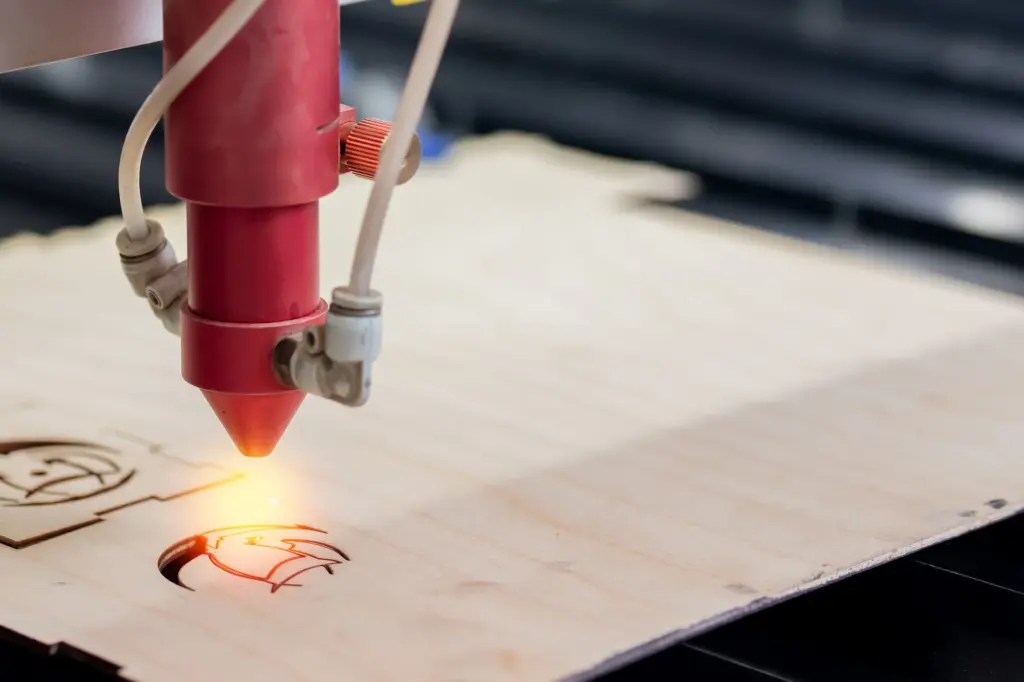

Laser Engraving

Process Description:

Laser engraving uses a focused laser beam to etch or vaporize material from the surface of the workpiece. The laser is controlled by a computer, which allows it to follow precise patterns and designs. Laser engraving provides an extremely high level of detail and precision without making direct contact with the workpiece.

Machines Used:

- CO2 Laser Engravers: Ideal for engraving non-metallic materials like wood, acrylic, and plastic.

- Fiber Laser Engravers: Best suited for metal engraving, including stainless steel, brass, and aluminum.

Applications:

- High-precision engraving of logos, text, and intricate patterns on metals, plastics, and wood.

- Personalized gifts, awards, and promotional products.

- Identification markings on parts in the automotive, aerospace, and medical industries.

- Fine details for engraving on jewelry, watch faces, and other consumer goods.

Key Features:

- Extremely fine detail and precision (down to micrometers).

- No physical contact with the material, reducing wear on both the tool and workpiece.

- High-speed engraving with minimal setup time, ideal for high-volume production runs.

- Clean, precise, and consistent results across a range of materials

Chemical Engraving (Etching)

Process Description:

Chemical engraving (or etching) involves applying a protective mask to a surface and using a chemical solution to selectively remove material from exposed areas. This method allows for very fine, intricate designs and can be used to etch parts that are difficult to machine by conventional methods.

Machines Used:

- Chemical Etching Systems: Automated systems used for large-scale production of etched parts. These systems typically use acid or other chemicals to etch the material.

Applications:

- Precision engraving on delicate or hard-to-machine materials such as metals, ceramics, and composites.

- Creating patterns, logos, and identification marks on flat surfaces.

- High-precision etching for circuit boards, electrical components, and other technical applications.

Key Features:

- Ideal for intricate designs, fine lines, and complex patterns.

- Effective for high-volume production with consistent results.

- Minimal tool wear, as the process does not involve direct contact with the material.

- Best for flat or thin materials.

Rotary Laser Engraving (Hybrid Process)

Process Description:

Rotary laser engraving combines the precision of laser engraving with the capabilities of rotary engraving machines. It involves using a rotary system to rotate the workpiece while the laser engraves the surface. This method is particularly useful for engraving cylindrical or rounded objects.

Machines Used:

- CNC Rotary Laser Systems: These systems use both a rotating axis and a laser for engraving on curved or cylindrical surfaces.

Applications:

Engraving on cylindrical objects like bottles, pipes, tools, and parts with rotational symmetry.

Marking of items such as jewelry, pens, and promotional items.

Personalized engraving on curved surfaces.

Key Features:

Ideal for engraving on curved or cylindrical surfaces.

Combines the versatility of rotary engraving with the precision of laser engraving.

Provides high-quality, permanent markings

Micro Engraving

Process Description:

Micro engraving involves the use of extremely fine tools or laser beams to create small, detailed engravings, often requiring the ability to work at the microscopic level. This process is used when the engraving needs to be extremely precise and is commonly used in electronics, medical devices, and watches.

Machines Used:

- Micro CNC Engraving Machines: Specially designed for engraving extremely fine features and tiny text or patterns.

- Micro Laser Engraving Machines: Used for engraving extremely small text and patterns at very high resolution.

Applications:

Fine text and serial numbers on medical instruments and implants.

Micro logos and designs on electronic components, circuit boards, and jewelry.

Engraving of small-scale, high-precision components

Key Features:

Capable of producing highly detailed and fine text, logos, and patterns ▪ Suitable for very small workpieces or highly intricate designs.

High-precision for use in industries where accuracy at the micro level is required.