Turning Services

Turning Services

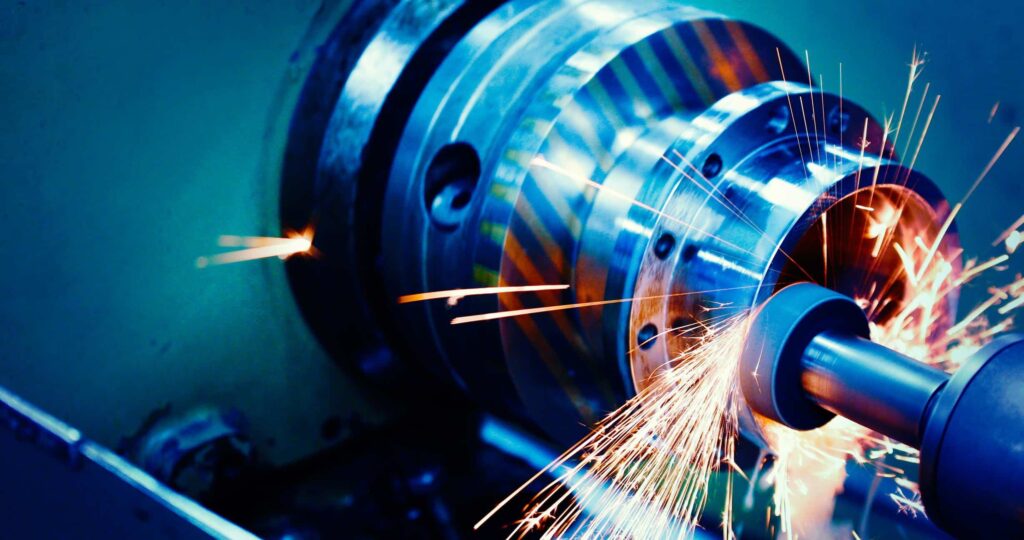

Turning is a fundamental machining process widely used in manufacturing to produce cylindrical and conical parts with high precision. It involves removing material from a rotating workpiece using a cutting tool, typically a single-point tool. This process is applied in producing components for various industries, including aerospace, automotive, medical, and energy. Our turning services cater to a wide range of materials and applications, providing high-precision solutions that meet the most stringent industry standards. This catalogue provides detailed insights into the turning processes, the machines used, and their specific applications.

Materials Processed:

- Metals:

– Stainless steel (SS316, SS304), Carbon steel, Aluminum, Titanium, Brass, Copper, Inconel - Plastics:

– PEEK, PTFE, Delrin, Nylon, ABS, Polycarbonate - Exotic Materials:

– Tool steels, ceramics, high-temperature alloys, and composites

- Maximum Diameter: Up to 1,000 mm

- Maximum Length: Up to 3,000 mm

- Surface Finish: As fine as 0.2 µm Ra

- Tolerance Accuracy: ±0.005 mm

Low to High-Volume Production: From prototypes and small batches to large production runs

Straight Turning

Process Description: Straight turning is the most common turning operation, where the tool moves along the length of the workpiece to reduce its diameter. The process is ideal for producing cylindrical parts with a uniform diameter.

Machines Used:

- CNC Lathes (Computer Numerical Control Lathes): These machines provide high precision, automated control for consistent results in mass production and complex geometries.

- Manual Lathes: Often used for simpler tasks, such as one-off or low-volume production. ∙

- Vertical Turning Lathes (VTL): Used for larger workpieces requiring high torque and precision.

Applications:

Shafts, rods, and cylindrical components

Parts requiring high dimensional accuracy and smooth finishes

Key Features:

High tolerance and surface finish

Uniform diameter along the length of the workpiece

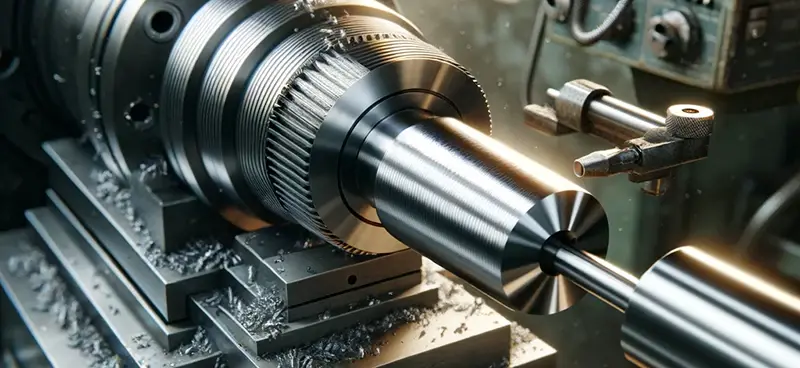

Taper Turning

Process Description:

Taper turning involves gradually reducing the diameter of a workpiece from one end to the other to create a conical shape. This can be achieved by tilting the cutting tool or adjusting the lathe settings to control the taper angle.

Machines Used:

- CNC Lathes: For precise control of taper angles and lengths.

- Manual Lathes with Taper Attachments: Suitable for simpler, small-volume tasks where the taper angle is not complex.

Applications:

- Tool handles, spindles, and machine parts

- Aerospace components requiring custom tapers

Key Features:

- Precise control over taper angles

- Smooth transitions between different diameters

Grooving

Machines Used:

- CNC Lathes: Equipped with grooving tools for high precision and automation. ∙

- Manual Lathes: For simple, non-automated grooving tasks.

Applications:

- Keyways, O-ring grooves, and snap-ring grooves

- Decorative patterns and grooves

Key Features:

- High precision in width and depth of the groove

- Capability to create both axial and radial grooves

Thread Turning

Machines Used:

- CNC Lathes: Equipped with specialized threading tools for automated, high-precision thread cutting.

- Swiss-Type Lathes: Ideal for high-precision, small parts with complex thread profiles.

Applications:

Bolts, nuts, threaded rods, and fasteners

Precision parts with custom thread profiles

Key Features:

High precision for thread pitch and geometry

Capability for internal and external threading

Parting/Cut-Off

Process Description:

Parting or cut-off is used to separate a finished part from the raw stock or to cut the material into desired lengths. The parting tool cuts through the workpiece, usually at the end of the machining process.

Machines Used:

- CNC Lathes: Provide precision and consistency for parting off.

- Manual Lathes: Often used for simpler, low-volume parting tasks.

Applications:

∙Separating finished parts from bars or blanks

Cutting material into precise lengths

Key Features:

Clean cuts with minimal material wastage

High precision in part separation

Boring

Machines Used:

- Vertical Turning Lathes (VTL): Ideal for large or heavy workpieces that require high torque during boring operations.

- CNC Lathes: Equipped with boring bars and tools to achieve high-precision results

Applications:

Valve bodies, bushings, and cylinders

Precision holes for bearing fits or mounting

Key Features:

High concentricity and dimensional accuracy

Smooth internal finishes

Facing

Process Description:

Facing is a process that cuts a flat surface across the end face of the workpiece, typically perpendicular to its axis. This is done to prepare the workpiece for further machining or to achieve a smooth, flat surface.

Machines Used:

- CNC Lathes: For automated, high-precision facing operations.

- Manual Lathes: For simpler, one-off tasks requiring a flat, smooth surface.

Applications:

Preparing surfaces for assembly or further machining

Creating flat surfaces for precision components

Key Features:

High-quality surface finishes

Achieves flatness and perpendicularity to tight tolerances

Drilling (on Lathes)

Process Description: Drilling on a lathe involves using a rotating tool to create holes in the workpiece. This operation is typically used in conjunction with other turning processes to produce parts with high hole accuracy.

Machines Used:

CNC Lathes with Live Tooling: For automated, high-precision drilling with various hole sizes.

Manual Lathes: For simpler drilling tasks on smaller workpieces.

Applications:

Holes for fasteners, pins, and bolts

Lubrication passages, mounting holes, and boreholes

Key Features:

High concentricity and accuracy

Capable of drilling deep and small-diameter holes

Knurling

Process Description: Knurling is used to create a textured pattern on the surface of a workpiece. It provides both functional and aesthetic benefits, such as enhancing grip or creating decorative patterns.

Machines Used:

- CNC Lathes: For precise and automated knurling, ensuring consistent patterns.

- Manual Lathes: Suitable for simpler knurling operations.

Applications:

∙ Tool handles, knobs, and components requiring better grip

Decorative parts for consumer goods

Key Features:

Durable, consistent patterns

Customizable patterns (e.g., straight, diamond, crosshatch)

Complex Contour Turning

Process Description: Complex contour turning involves producing intricate, multi-radius profiles and custom contours on the workpiece. It is suitable for parts with irregular or complex shapes.

Machines Used:

CNC Lathes: Provide the flexibility and precision needed for multi-radius and custom contours.

Swiss-Type Lathes: Ideal for high-precision, small parts requiring complex shapes.

Applications:

Aerospace components with complex geometries

Automotive and medical parts with custom profiles

Key Features:

High precision for irregular shapes and multi-radius profiles

Flexible for custom and complex part designs