EDM Spark Erosion Services

EDM Spark Erosion Services

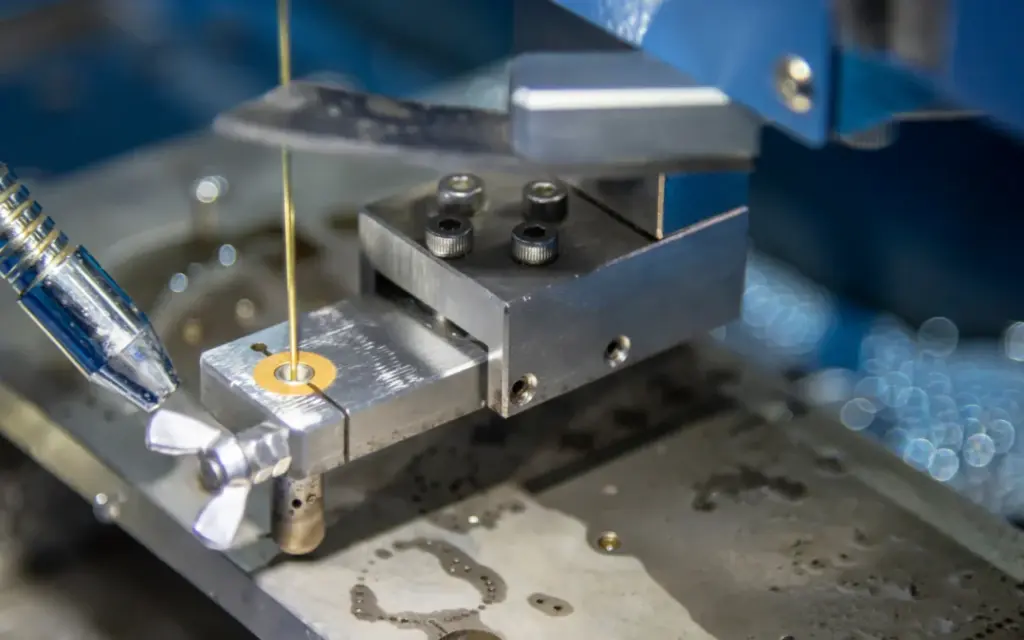

Electrical Discharge Machining (EDM) Spark Erosion is a highly precise machining process used to remove material from a workpiece by utilizing controlled electrical discharges (sparks). EDMspark erosion is ideal for producing intricate, complex, and delicate shapes, especially in hard, conductive materials that are difficult to machine by conventional methods. The process is particularly beneficial in industries such as aerospace, automotive, medical, and mold-making, where high precision, fine details, and tight tolerances are required.

Our EDM spark erosion services offer unparalleled precision and quality in machining, enabling the creation of parts with high complexity, detailed features, and minimal thermal distortion.

Materials Processed:

- Metals: Tool steels, Stainless steels, Titanium, Copper, Brass, Aluminum, Inconel, and other conductive metals

- Exotic Materials: Hard alloys, High-temperature alloys, Carbide, and Beryllium copper .

- Non-ferrous Materials: Precious metals like gold, silver, and platinum ∙ Composite Materials: Conductive composites.

- Maximum Workpiece Size: Up to 1,200 mm x 1,200 mm x 800 mm (depending on the machine used)

- Maximum Workpiece Weight: Up to 500 kg

- Tolerance Accuracy: ±0.005 mm (depending on the complexity of the workpiece).

- Surface Finish: Ra values down to 0.2 µm, depending on material and process

- Low to Medium-Volume Production: Ideal for producing prototypes, small batches, and complex components.

- High-Precision Components: Suitable for applications requiring ultra-fine features and tight tolerances.

Wire EDM (WEDM)

Process Description: Wire EDM uses a continuous wire electrode, usually made of copper or brass, to cut through the workpiece. The wire moves in a precise, computer-controlled path, guided by an electrical discharge. The material is eroded away in a controlled manner by the sparking process, allowing for the creation of intricate shapes, profiles, and features.

Machines Used:

- CNC Wire EDM Machines: These machines are equipped with automated controls that allow for precise cutting along complex contours.

- High-Speed Wire EDM Machines: For high-speed cutting with fine wire for ultra-precise cuts.

Applications:

Cutting intricate and complex shapes such as gears, keyways, and profiles.

High-precision parts for the aerospace, automotive, and medical industries.

Manufacturing of molds, dies, and cavities for various industrial applications

Key Features:

High precision for fine geometries and tight tolerances.

Capable of cutting very hard materials (tool steels, carbide, etc.).

Ideal for producing parts with complex shapes or thin walls.

Minimal material wastage due to the precision of the wire.

Sinker EDM (Sinker or Die-Sinker EDM)

Process Description:

Sinker EDM uses a specially shaped electrode, usually made of copper, graphite, or tungsten, to erode the material. The electrode is submerged in the workpiece and moved in a controlled manner by CNC to achieve the desired shape. This process is used for producing cavities, molds, and complex 3D features.

Machines Used:

- CNC Sinker EDM Machines: These machines are used for highly detailed and complex cavity and contour machining.

- High-Precision Sinker EDM Machines: These machines provide fine control over electrode movement for detailed and intricate designs.

Applications:

- Manufacturing of molds and dies, including precision cavities and complex features.

- Aerospace and automotive parts requiring complex 3D shapes.

- Tooling for injection molding, casting, and stamping industries.

- Precision parts for medical devices and implants.

Key Features:

- High precision for creating intricate and complex 3D shapes.

- Minimal thermal impact on the workpiece.

- Capable of machining hard materials that are difficult to process with traditional machining methods.

- Ideal for creating cavities, complex contours, and deep holes.

EDM Hole Drilling (EDM Drilling)

Process Description:

EDM Hole Drilling is a specialized process used for creating small-diameter holes, often in hard or tough materials. The process uses a rotating electrode to drill holes using a series of spark erosions, creating clean, precise, and burr-free holes without the need for pre-drilled holes or mechanical pressure.

Machines Used:

- CNC Hole Drilling EDM Machines: Specialized machines for drilling holes with high precision and minimal heat generation.

- Automatic Drilling EDM Machines: Machines capable of drilling a series of small holes with high accuracy.

Applications:

- Drilling small holes in aerospace, automotive, and mold-making components ∙ Creating cooling holes for aerospace turbine blades and heat exchangers ∙ Drilling through hard materials such as tool steel, carbide, and titanium ∙ Medical applications like drilling small holes in implants and surgical tools

Key Features:

- Ideal for creating small-diameter, deep, and precise holes.

- Minimal thermal distortion and burr formation.

- Suitable for tough, hard-to-machine materials.

- High accuracy and repeatability for small-hole drilling.

EDM Tapping

Process Description:

EDM Tapping uses the EDM process to tap threads into a workpiece. The process uses an electrode that functions as a tap, with controlled electrical discharges eroding the material to

form internal threads. This is particularly useful for tapping holes in materials that are too hard or too difficult to machine with conventional methods.

Machines Used:

- CNC EDM Tapping Machines: Specialized EDM machines designed to perform tapping with high precision.

- EDM Sinker Machines with Tapping Capabilities: Sinker EDM machines that can also be used for tapping operations.

Applications:

Tapping threads in hardened steel, carbide, and exotic materials.

Producing precise internal threads in molds and dies.

Ideal for aerospace and automotive applications where traditional tapping is not possible due to material hardness.

Key Features:

High precision for tapping internal threads.

Capability to tap hard materials that are difficult to machine conventionally.

Suitable for intricate, fine-thread designs in tight spaces.